Share this

Troubleshooting Problems with Flexo Printing on Corrugated

by Luminite on Aug 30, 2019 1:51:27 PM

Before the adaptation of flexographic printing for commercial packaging use, printing on corrugated substrates was highly troublesome.

The delicate material would either be crushed during the printing process or printing had to be done so lightly that graphics were limited to simple, unappealing designs and text that made use of only one or two colors.

Flexographic printing has made it possible to achieve much higher resolution, multi-color, intricate images and text on corrugated substrates without harming the integrity of the materials. In spite of its seemingly limitless possibilities, flexo printing on corrugated still has its own set of challenges.

If you're experiencing issues with flexo printing on corrugated materials and not achieving the printing results you desire, consider the following troubleshooting tips.

Top 4 Culprits: Troubleshooting Problems with Flexo Printing on Corrugated Substrates

1. Ink

If your print has a streaky appearance, washboard-like look, or spotty, uneven inking, you likely have an issue with the ink's compatibility with the project. Using inks that are incompatible with your image carrier and/ or substrate can leave smears across your print.

In addition, using contaminated ink can result in foreign particles or hickeys on your finished products.

2. Printing Plates

It's important to check plates before every print run and to maintain them properly. Dirty, damaged, soft, uneven, worn, or loose plates can lead to dirty prints, spotty printing, washboard effects, uneven ink transfer, streaking, and image bleeding.

Switching to more durable, elastomer printing sleeves may also be a solution to consider.

3. Ink pH

If you're finding uneven color deposits, smeared images, streaking, or image bleeding, and your printing plates are in good shape, then your ink's pH could be to blame. The pH level of ink affects how quickly or slowly ink dries and how well the color will absorb and stick to your substrate.

Ink that dries too quickly or too slowly could be at the heart of your corrugated print run troubles.

4. Viscosity

Ink viscosity affects how well ink deposits on and clings to your substrate, and different substrate materials with different surface tensions call for various levels of viscosity. If your viscosity is too low, your print runs might have trouble with foaming, abrasion, spotty ink deposits, or uneven appearance.

If ink viscosity is too high, you could face similar issues plus smeared ink, uneven color, color that's darker than expected, halos, fisheyes, and contaminants in the ink.

How to Improve Common Corrugated Printing Problems

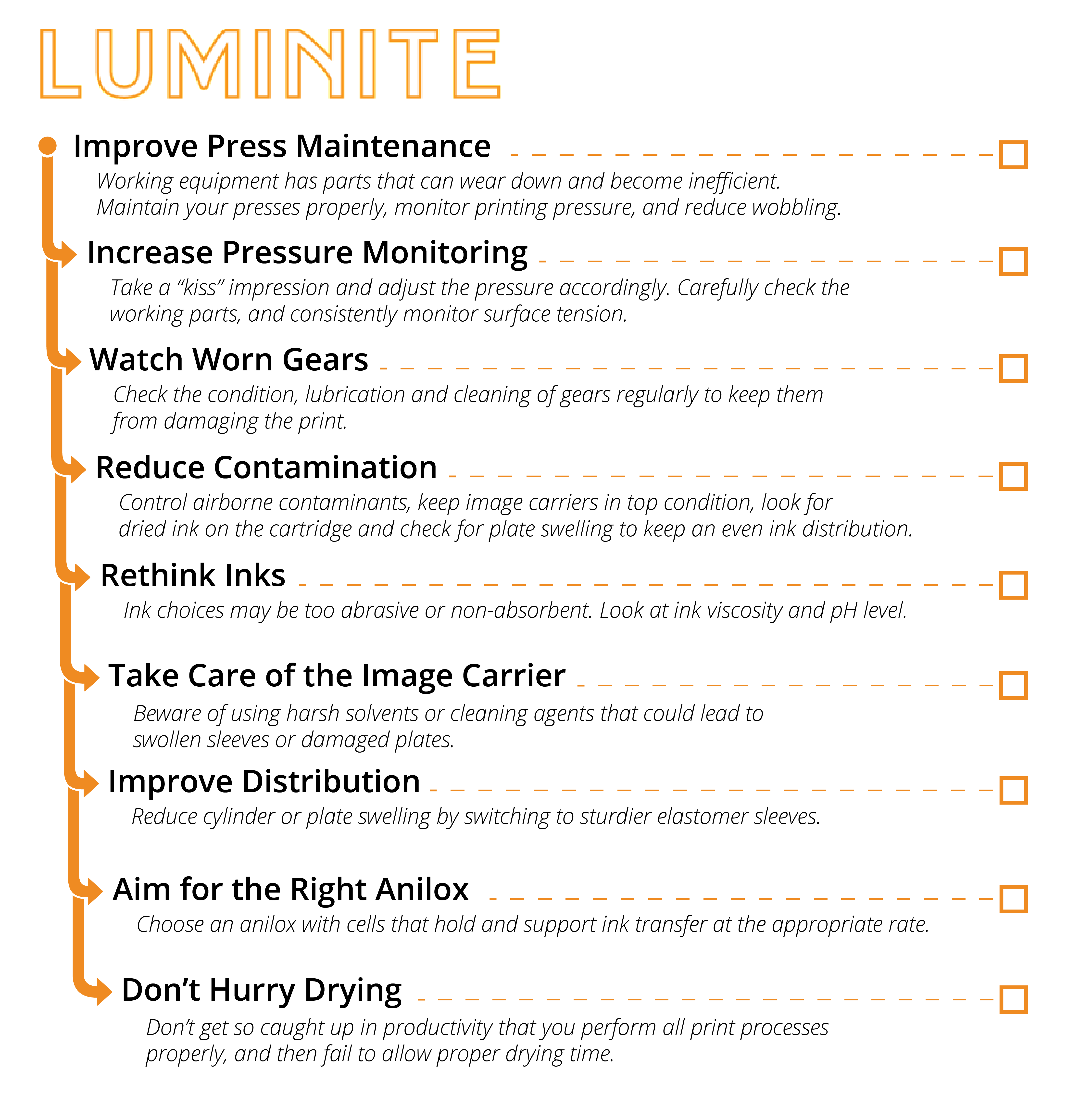

- Improve press maintenance: Working equipment has parts that can wear down and become inefficient. Maintain your presses properly, monitor printing pressure, and reduce wobbling.

- Increase pressure monitoring: Take a “kiss” impression and adjust the pressure accordingly. Carefully check the working parts, and consistently monitor surface tension.

- Watch worn gears: Check the condition, lubrication and cleaning of gears regularly to keep them from damaging the print.

- Reduce contamination: Control airborne contaminants, keep image carriers in top condition, look for dried ink on the cartridge and check for plate swelling to keep an even ink distribution.

- Rethink inks: Ink choices may be too abrasive or non-absorbent. Look at ink viscosity and pH level.

- Take care of the image carrier: Beware of using harsh solvents or cleaning agents that could lead to swollen sleeves or damaged plates.

- Improve distribution: Reduce cylinder or plate swelling by switching to sturdier elastomer sleeves.

- Aim for the right anilox: Choose an anilox with cells that hold and support ink transfer at the appropriate rate.

- Don't hurry drying: Don’t get so caught up in productivity that you perform all print processes properly, and then fail to allow proper drying time.

Flexo Problem Still Not Solved?

Flexo printing — especially on corrugated substrates — requires a delicate balance of several components all working in harmony. For a print run to turn out exactly as expected, all components have to be exactly right.

That means pairing the proper ink viscosity with the right surface tension, storing inks as instructed, always using compatible inks, proper maintenance and cleaning of printing plates, and more.

For more information about troubleshooting your corrugated substrate print run problems or other concerns, contact a flexographic printing expert at Luminite.

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (1)